Product Search

Product categories

Evodurance Drill Bit AO Quick Release

£30.00

Our popular Evodurance® range has been improved, they still cut quickly and precisely as before but they have been strengthened to ensure even the

most heavy-handed surgeon can use them. Drills are coated in TiN (Titanium Nitride)

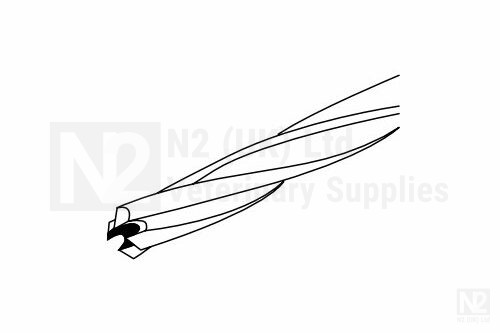

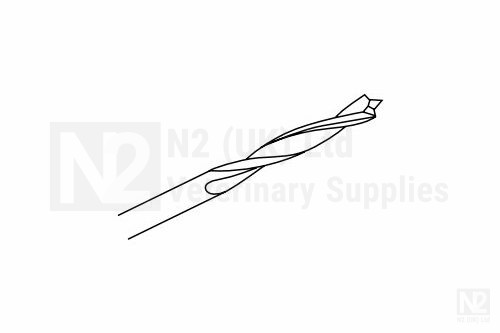

EVODURANCE® Drill Bits

Next Generation

Most Orthopaedic operations involve drilling before the insertion of screws/pins/accessories into bone. The challenge was to create a superior drill than what is currently available. The current drills have been around for decades and uses old technology without taking advantage of modern CNC grinders to create complex geometry and angled cutting flutes. Investment in medical technology has always been in the human market, leaving the Veterinary market

requirements far down the list of priorities. It is known that a rise in temperature above 43°C around a drill hole will cause Thermal Bone Necrosis, with irreversible changes in the structure and physical properties of bone. The immediate effect on the physical structure and the later effect on the cellular components both prejudice the hold of the screw as necrotic bone is reabsorbed, reducing the stability and strength of the fixation. Also the presence of necrotic tissue may delay healing and be predisposed to infection.

Causes and solutions

- Blunt drill bits will generate higher temperatures and the increased force required for penetration causes poor control of the drill, and uncontrolled bursting through the far cortex.

Solution: Evodurance® Drill Bits (EDB) complex cutting Geometry ensures concentricity, speed and accuracy. It is highly recommended to use a drill stop until you are confident in the increased performance. - Blocked Flutes: The physical characteristics of bone vary considerably with its state. When drilled dry, it produces debris in small particles that are easily cleared by a drill bit and the optimal helix angle for the flute is a slow helix (less turns per revolution) which most standard Orthopaedic drill bits have. However, at the site of operation, the debris is wet and mixed with medullary fat and bio-fluids. In this state, bone debris is no longer in the form of small particles and the flutes of a slow helix drill will clog easily and generate excessive heat.

Solution: Evodurance® Drill Bits (EDB) have a quick helix in the form of a parabolic flute. - Increased force and wear. Standard drill points require more force to penetrate the bone because the contact surface area is larger, generating more friction, and the cutting edge does not run across the central section. If the angles are too sharp, they can cause soft tissue trauma when bursting through the far cortex. Also a more pointed tip will blunt more quickly.

Solution: Evodurance® Drill Bits (EDB) have a 100ᴼ point angle and our PVD coating with biocompatible TiCN resulting in further reduced friction generated heat and drastically improving tool life.

At N2 UK Ltd we believe we are the first veterinary manufacturer to invest resources in the improvement of bone drills. Our drills will be more efficient, generate minimal friction and reduce the production of thermal energy. We are pleased to say that this style of drill is now available from our Evodurance® Drill Bit range.

Related products

Standard Economy Drill

Cannulated Drill Bits

Anti Skid Drill Bits

Selection of Drill Bits

| Diameter (mm) | 1.5, 1.8, 2.0, 2.5, 2.7, 2.8 |

|---|---|

| Length (mm) | 80, 110, 150 |