Evolox® Locking System

Poly-Axial Locking Systems

Benefits

Reduced soft tissue irritation

Low profile plates with smooth rounded edges reduce soft tissue irritation, and aid wound closure.

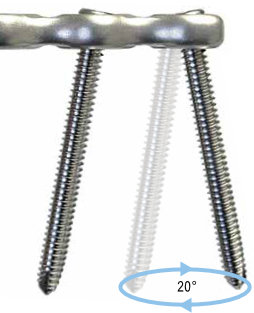

Variable angle

Screw holes allow up to 10° of directional angulation.

20° inclusive.

Fragment reduction

The Evolox® technology allows individual fragment fixation by allowing the screws to angle and lock towards the core of the bone rather than be limited to the perpendicular axis of the plate. This gives the plate coverage for multiple fracture configurations.

Secure fixation

The Evolox® technology creates a locked construct when used in conjunction with a compatible locking screw, providing angular stability, and a reduced risk of primary and secondary losses of reduction.

Preservation of blood supply

Locking plates do not need to be compressed against the bone to create a stable fixation, thus reducing plate to bone contact, which in turn reduces complications caused by vascular trauma to periosteal tissue.

Crumple zones

Plates in the EVOLOX range that require anatomical bending are designed with crumple zones that control the movement of the material during manipulation, and direct distortion away from the locking holes. Locking plugs should be used for added protection.

Pull out resistance

By opposing screws in varying angular directions using the Evolox® system the perpendicular pull out resistance is greatly increased. Combine this with a locked construct and the reduction of the fracture becomes a reliable fixation in osteoporotic bone. This would not be recommended for other systems with monoaxial direction.

Plate bending

The need to bend the plates to an accurate anatomical form prior to implantation is greatly reduced as the need to generate compressive forces between plate and bone is not required. The Evolox® technology can be angled toward the fragment and still create a stable fixation. The reduced bending requirement also helps to retain the full strength of the plate and protect it from stress risers that can cause premature implant failure.

Satin Finish

In addition to the obvious non-reflective surface providing less light glare during surgery, the uniform surface layer of compressive stress acts to combat stress cracks and corrosion, therefore, increasing the life of implant. Also this type of surface finish has a greater ultrasound reflection. The process itself cleans the part, leaving it free from residues with a low CFU (microorganism) count, resulting in easier autoclave sterilisation.

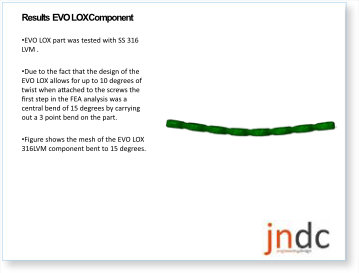

Evolox Gen 2® plates

2nd Generation Evolox® is our latest advancement in poly-axial locking technology. It is unlike any previous medical thread form seen in the market place.

The usual method to achieve poly-axial locking is to either:

- Create interrupts (breaks) in the thread form, thus allowing the mating thread to pass through the gap to the next thread.

- Self-cut the screw thread into the plate.

The method in system 1 incurs far less complications with removal of the screw and implant, as system 2 requires the plate to be of a softer material than the screw which then cold fuses the screw to the plate. This is what makes the screw difficult to remove. Also the softer plate is inherently weaker than if using harder material. This method is usually reserved for Titanium products, using pure Titanium on the plate and alloyed Titanium on the screws.

System 1 can have limitations, as the interrupts in thread form reduce the thread strength and can result in thread stripping if subjected to excessive load after placement or excessive torque during placement. Thread stripping although uncommon will weaken the overall construct. To avoid this occurrence where excessive load after placement is anticipated, it is usual to advise an increase in the plate size to the next range, ie 2.7mm to 3.5mm or 3.5mm to 3.5mm broad etc.

This is not always ideal for many reasons, including wound closure and poor bone stock. For this reason, N2 UK Ltd have strived to overcome this problem and increased the scope of its useability through innovative design and complex machining strategies. We are pleased to say that after several designs and prototypes we have achieved our goal. Our 2nd generation Evolox® hole system (patent pending) uses a unique twin start tapered triangular thread form that naturally generates the space required to allow the threads to skip to the next level, thus maintaining a continuous thread form and drastically improving the rigidity of the locking interface.

This has allowed N2 UK Ltd to expand its range of poly-axial plates extensively into the 2.7mm and 2.4mm categories.

Evolox® is a registered Trademark of N2(UK)Ltd

Evolox® is a registered Trademark of N2(UK)Ltd